Securing a sustainable manufacturing future through resilient supply chains

Daphne Vlastari, Head of Communications and Government Relations, UK & Ireland

| BASF

In January 2024, the UK Government released the ‘UK critical imports and supply chains strategy’ developed with the input of a number of business stakeholders. The fact that this is the UK’s first strategy of this nature makes it even more welcome.

The strategy recognises the complex world within which businesses, including critical sectors of the economy such as chemicals and energy, operate and the recent disruptions they have had to weather. As the strategy explains, this changed business environment is a result of geopolitical developments but also the critically important transition phase that we are in in terms of developing the green technologies that we will need for a net zero future.

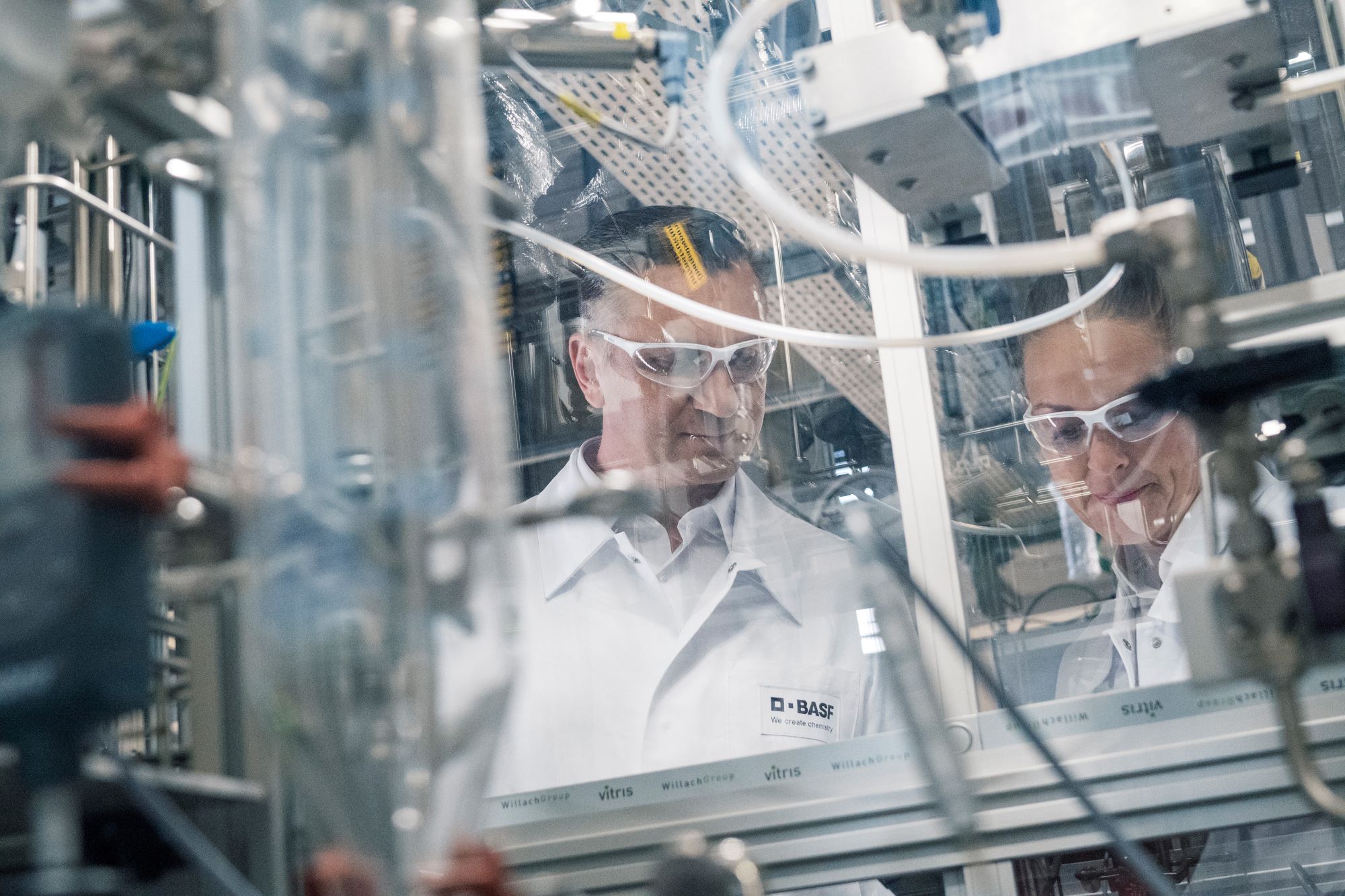

As a major multinational company operating in most countries of the world and with large integrated chemicals manufacturing sites in Europe, North America and Asia, BASF is one of the businesses that has had to navigate these challenges. To provide a sense of the scale of operations, in 2022, BASF purchased a total of around 35,000 different raw materials from more than 6,500 suppliers to provide customers with solutions across almost all industries from construction and automotive to healthcare and nutrition. While not always acknowledged, chemicals are used in 96% of all manufacturing products. A resilient chemicals value chain is therefore key for a successful manufacturing industry.

Credit: BASF SE

Credit: BASF SE

As the strategy rightly points out, it is the responsibility of businesses to manage their supply chains, with government intervention an option when there is a market failure and to ensure regulatory and trade barriers are minimised. For example, at BASF our strategy covers the entire value chain – from responsible procurement and the efficient use of raw materials in our own processes and recycling by-products to developing resource-saving solutions for our customers. This is so that we can realise our aim to decouple growth from resource consumption with process and product innovations and to accelerate the shift towards closed-loop systems.

However, the right regulatory environment can greatly support (or hinder) supply chain resilience. This is particularly important for the chemicals sector as the breadth of products and solutions provided depends on complex and interlinked value chains across different geographies – and this is not always clearly understood. Because the manufacture of a single chemical product can be multi-layered there is a reliance throughout the value-chain for robustness, competitiveness, and efficiency.

For example, our plant in Callanish on the Isle of Lewis plays an integral part in BASF’s Omega-3 production process. BASF has two manufacturing sites producing our Omega-3 oils – Callanish and Sandefjord, Norway - ensuring we can offer a wide portfolio of products to the pharmaceutical and nutrition industries. The two plants while located in different areas and producing different products are closely linked. This is because fish oils sourced from well-managed and certified fisheries are processed at our plant in Sandefjord. Through several purification steps, impurities are removed to produce highly concentrated products. This intermediate is then used by the team at our Callanish site to make the final, high-purity product. The same applies with even greater complexities to most chemical products which rely on a number of different actors in the value chain. The multiple applications of polyurethane solutions which range from construction, automotive to leisure, seating, offshore and marine industries is another way to illustrate this. The different chemistry needed to respond to the specific needs of these industries from safety to performance and sustainability can only be achieved with a robust and resilient supply chain.

Credit: BASF SE

Credit: BASF SE

So regulatory barriers, for example in terms of trade and standards, can have profound implications on the viability and resilience of chemical supply chains. Predictable and consistent policy-making to enable smooth and barrier-free trading can minimise supply chain disruptions and reduce risks. It is very positive that this is recognised by the Critical Imports and Supply Chains Strategy which states that ‘The sector is also a prime example of an industry that benefits from both reducing barriers to trade and having a supportive domestic ecosystem for business growth’.

At the same time, government can enhance the resilience of supply chains through innovation. Innovative manufacturing methods such as flow chemistry have the potential to complement traditional large volume chemicals manufacturing. This is why projects such as the BASF led IConIC consortium, supported by EPSRC funding are another important part of the solution.

Beyond R&D, one area that deserves greater attention is the concept of circularity. While the role of the circular economy is referenced in the strategy, there is more that government can do to realise its potential for contributing to supply chain resilience. The time is right for stakeholders and government to work together on a policy vision for circularity; to articulate the policy changes that are required to support sectors such as chemicals towards becoming more circular.

Companies like BASF are implementing programmes to decouple growth from resource consumption and developing more circular products that make the most of our planet’s limited resources by keeping them in use for as long as possible and minimising waste. But government can accelerate this process by supporting a package of policies that can make this transition smoother. For the chemicals industry, this will mean looking at the raw materials the sector depends on and looking at the alternatives, from recycled and renewable feedstock options to areas that hold significant potential such as the use of captured CO2. It also means looking at how we ensure that we are able to recover and recycle precious materials and minerals and how those can be used to power the net zero technologies of the future. Circularity offers the opportunity of combining economic success with sustainability and competitiveness. It is not an opportunity that we should miss out on.

PoliticsHome Newsletters

Get the inside track on what MPs and Peers are talking about. Sign up to The House's morning email for the latest insight and reaction from Parliamentarians, policy-makers and organisations.